Anechoic Chambers Present Unique Challenges for Sprinker Systems

For years research organizations and industry have used anechoic chambers to conduct research and testing on technology that directly impacts society and the environment. The unique environment of anechoic chambers allows precise and demanding testing of the technology of today, by offering an ambient free and echo-free enclosure.

The necessary sound absorption level of 99% to 100%, or a reflected sound pressure level of 10% or less, is created by lining walls, ceiling and floors with deep sound absorbing wedges or panels. This presents special challenges for effective sprinkler systems that must extend beyond these materials in order to quickly mitigate any fire or smoke hazard.

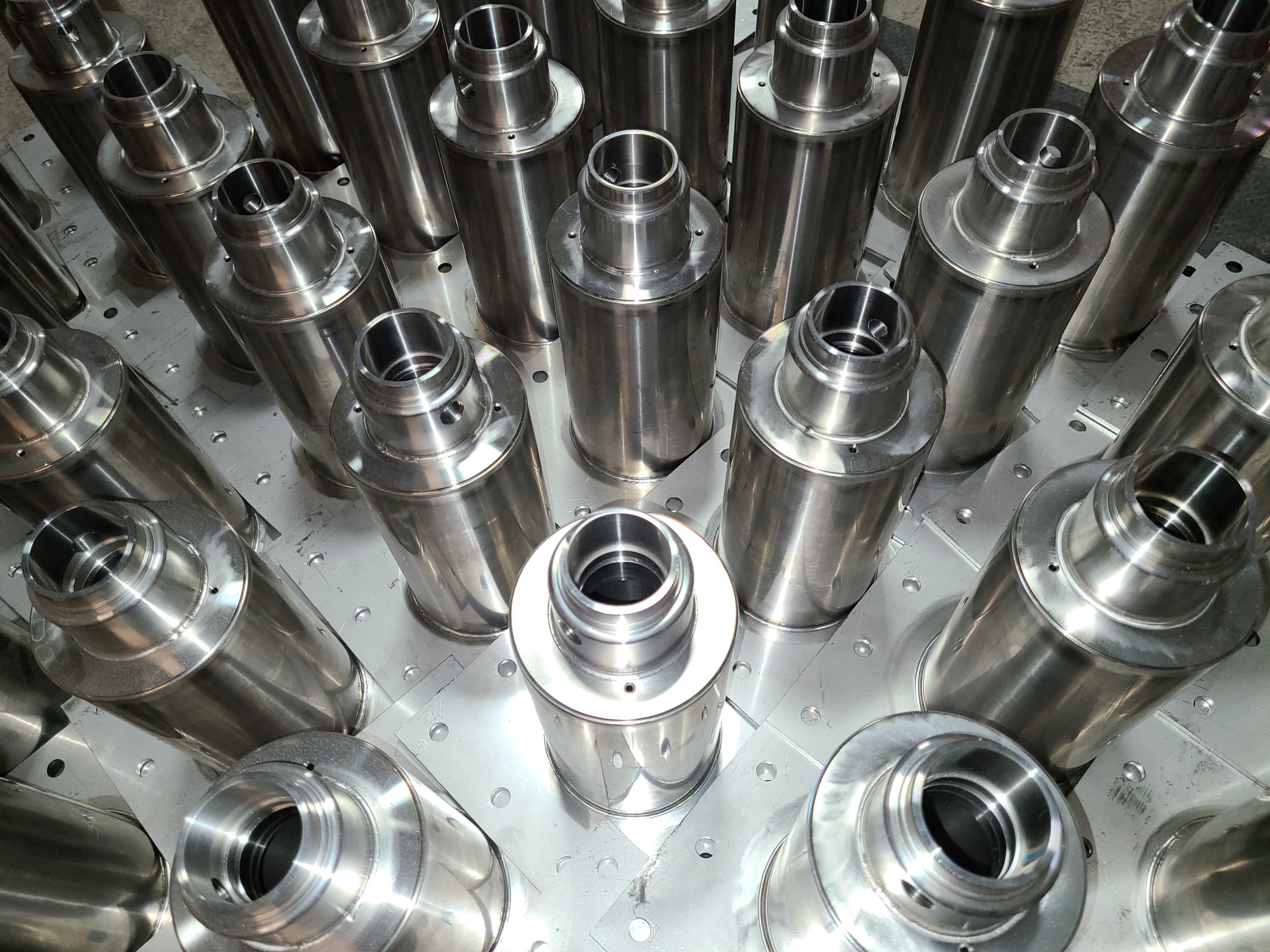

Sprinkler Innovations Retractable Telescoping Sprinkler Assembly meets these special challenges head on, and answers them with innovative technology to improve the competency of your anechoic chamber.

Anechoic Chambers Present Unique Challenges for Sprinker Systems

Test the sprinkler system with a minimum disruption of anechoic testing.

The regular trip tests necessitated by anechoic materials cause disruptions and delays in anechoic testing and cut into profitable testing schedules. Sprinkler Innovations Retractable Telescoping Sprinkler Assemblies present an immediate solution to this problem.

The Retractable Telescoping Sprinkler Assembly automatically retracts and resets itself. The trip test is run, and when the system is depressurized, the Retractable Telescoping Sprinkler Assembly resets itself. There is no need to remove items or anechoic materials from the chamber in order to reset the sprinkler assemblies.