Innovations

Since moving to our new facility in Las Vegas, Nevada, we have improved many of our manufacturing processes that include:

Laser cutting stainless steel tubing offers several advantages:

- Precision and Accuracy: Laser cutting provides high precision, allowing for tight tolerances in applications requiring exact specifications.

- Minimal Heat Affected Zone (HAZ): The focused nature of laser cutting means less heat is transferred to the surrounding material, reducing warping or distortion of the tubing.

- Environmentally Friendly: Laser cutting generates less waste and requires fewer finishing processes, making it a more sustainable option compared to some traditional cutting methods. Overall, laser cutting stainless steel tubing is an effective method for achieving high-quality results.

Innovations

Since moving to our new facility in Las Vegas, Nevada, we have improved many of our manufacturing processes that include:

Laser cutting stainless steel tubing offers several advantages:

- Precision and Accuracy: Laser cutting provides high precision, allowing for tight tolerances in applications requiring exact specifications.

- Minimal Heat Affected Zone (HAZ): The focused nature of laser cutting means less heat is transferred to the surrounding material, reducing warping or distortion of the tubing.

- Environmentally Friendly: Laser cutting generates less waste and requires fewer finishing processes, making it a more sustainable option compared to some traditional cutting methods. Overall, laser cutting stainless steel tubing is an effective method for achieving high-quality results.

Mounting Template – Sprinkler Innovations has created a specialized reusable drilling template designed to give installers unmatched accuracy and precision when drilling mounting holes. This innovative magnetic tool simplifies the installation process, ensuring that your mounting holes are drilled correctly. This template is available for purchase, please inquire about it when requesting your quote.

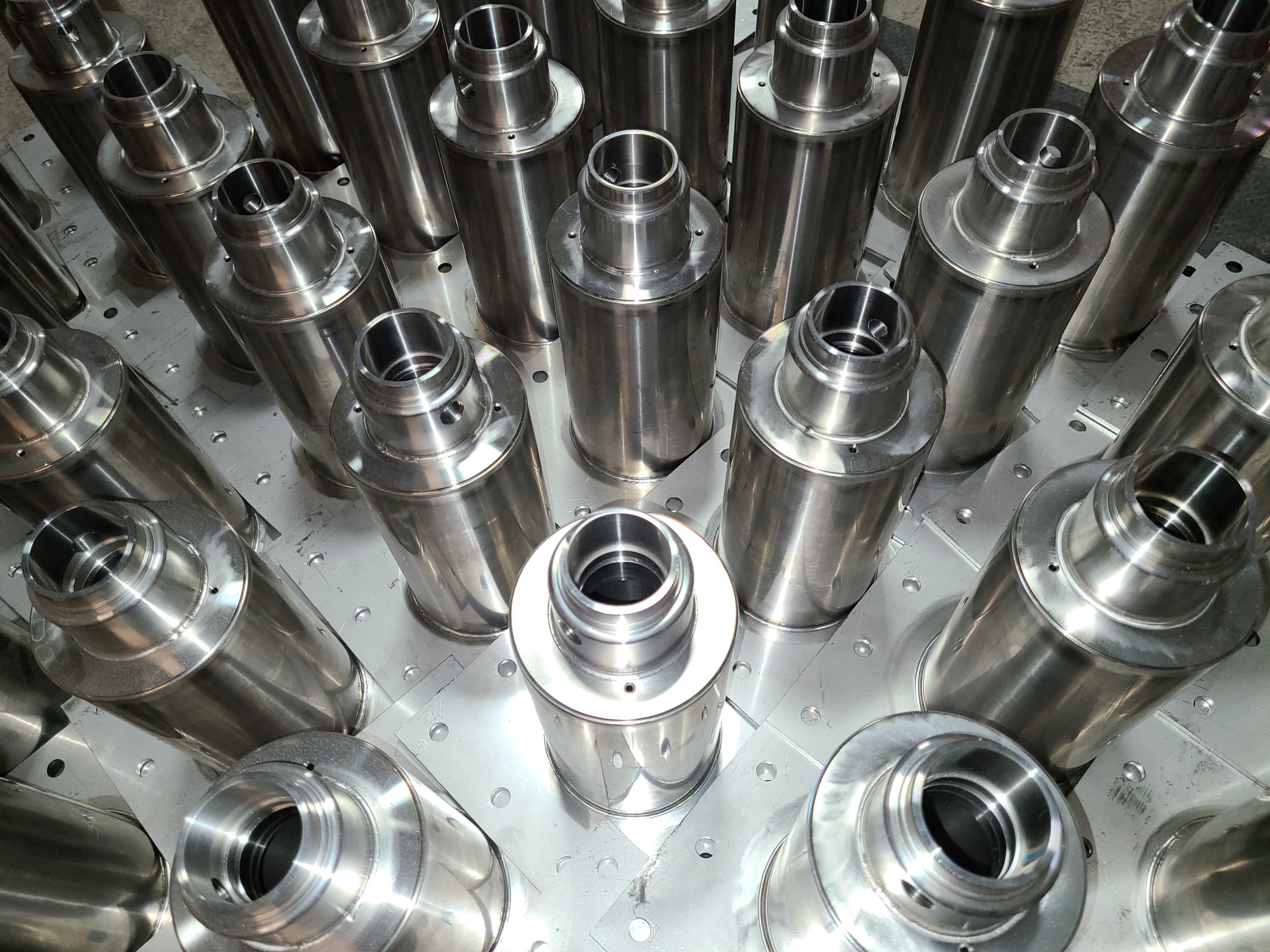

Engineered Manufacturing Templates – Have been developed at Sprinkler Innovations and implemented into all facets of the manufacturing process. This offers several significant advantages:

- Consistency and Quality Control: Templates ensure that every piece produced is identical, reducing variability and improving overall quality.

- Increased Efficiency: Templates streamline the manufacturing process, reducing setup time and allowing for quicker production cycles.

- Scalability: Templates can be easily adapted for larger production runs, ensuring that quality and efficiency are maintained as demand increases.

Mounting Template – Sprinkler Innovations has created a specialized reusable drilling template designed to give installers unmatched accuracy and precision when drilling mounting holes. This innovative magnetic tool simplifies the installation process, ensuring that your mounting holes are drilled correctly. (find a pic of a drill, someone drilling into metal, etc.)

The use of our engineered template offers several significant advantages:

- Consistency and Quality Control: Templates ensure that every piece produced is identical, reducing variability and improving overall quality.

- Increased Efficiency: Templates streamline the manufacturing process, reducing setup time and allowing for quicker production cycles. This can lead to significant time savings.

In-Person on Site Training – Sprinkler Innovations now offers classroom style installation and product training. We will come to you and train your team on the methods and techniques required for proper field installation of our assemblies.